مسكن

>

Bentonite four-roll crusher

مسكن

>

Bentonite four-roll crusher

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

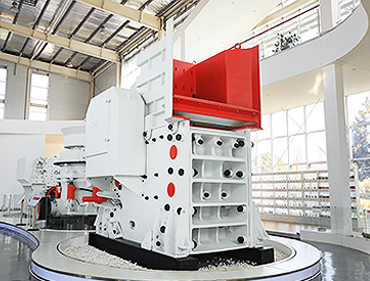

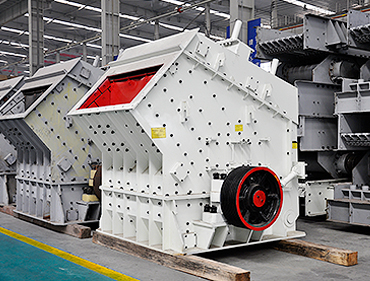

Bentonite four-roll crusher

CNU Roller structure of pair-roll crusher for bentonite

The utility model discloses a roller structure of a pair-roll crusher for bentonite, which comprises a roller body, a rotary shaft, end covers and a frame.

Roll Crusher an overview ScienceDirect Topics

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.2.3 Roll crusher circuit design. Roll crushers are generally not used as primary crushers for

进一步探索(PDF) Crushing and Screening Handbook Academia.eduRoll Crushers MetallurgistMineral Processing Engineer

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日The roll crusher has specially designed toothed rollers that can tear large pieces of bentonite clay into small pieces, effectively reducing the size of bentonite. It

Four roller crusher fine crushing 4PG roll crusher China

The four-roll crusher is actually a new type of equipment that combines a pair of roller crusher (double smooth roller crusher) and a double tooth roller crusher. It can be combined with two smooth rollers or one smooth

Bentonite Processing Methods And Required Equipment

2020年7月10日Crushing: Large pieces of bentonite are crushed by the crusher to the fineness that can enter the mill. 4. Grinding: The crushed small pieces of bentonite are

Fine Crushing Plant With Roll Crushers Eastman Rock Crusher

2022年5月20日Four Roll Fine Crusher. Maximum Feeding: Less than 60mm. Production Capacity: 2-350 (T / h) Performance Features: It has the characteristics of low use and

Bentonite Ore Products ECPlaza

Four roller crusher: The four roll crusher is actually a new type of equipment that combines a pair of roller crusher (double smooth roller crusher) and a double tooth roller

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日Four Roll crushers are designed for larger feed sizes and high ratios of reduction at high capacities. The top stage of the Four Roll crusher is essentially made up of a double roll crusher, which is

2pg 1000*1000 Big Double Roller Crusher for Bentonite

Product Description. Company Info. Basic Info. Model NO. 2PG1000*1000. Inlet Size. 250×400mm. Condition. New. Warranty. 12 Months. After-sales Service. Long Life Time.

CNU Roller structure of pair-roll crusher for bentonite

The utility model discloses a roller structure of a pair-roll crusher for bentonite, which comprises a roller body, a rotary shaft, end covers and a frame. The rotary shaft fixed onto the frame is fixed onto the end covers which are fixed to two ends of the cylindrical roller body respectively, an annular groove is arranged on the lateral side of the roller body,

Quad Roll Crushers McLanahan

It is the heaviest-duty model of Quad Roll Crusher that McLanahan makes, but it is not intended for very hard or abrasive rock. Designed for high-capacity applications, the Super Quad Roll Crusher is capable of

Roll Crushers / Granulators Ludman Industries High

Four-high precision grinding mill Likewise, the Roll Crusher or Granulator is a common size reduction unit, which can successfully process a variety of materials. Additionally, the differential speed of smooth or corrugated

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

11.25 Clay Processing US EPA

Bentonite is aclay composed primarily of smectite minerals, usually montmorillonite, and is used largely in drillingmuds, in foundry sands, and in pelletizing taconite iron ores. Fuller’s earth is defined as a nonplasticclay or claylike material that typically is high in magnesia and has specialized decolorizing andpurifying properties.

Roll Crusher HRC

Materials to be crushed are becoming more and difficult to process, high throughput capacities are required. High focus is now placed on energy consumption, and the use of energy-efficient roll crushers, with high throughput rates, is becoming increasingly important from an economic and ecological point of view.

Fine Crushing Plant With Roll Crushers Eastman Rock Crusher

2022年5月20日Four Roll Fine Crusher Introduction. The four roll crusher is suitable for ultra-fine crushing of solid materials with compressive strength less than 260mpa and moisture content less than 20%, such as crushing iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal silicon, barite, basalt, granite, steel slag, water

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

The Raymond® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日The roller crusher is suitable for crushing brittle block materials in cement, chemical industry, electric power, mine, metallurgy, building materials, refractories, coal mines, and other industries. It has a

Roll Crushers Top 2022 Models 911 Metallurgist

US$ 12,000. 8″ Laboratory Roll Crusher. 10″ to 12″ Double Roll Crushers. US$ 27,000. Roll Crusher for Sale. The standard spring roll crusher have two horizontally mounted cylinders. The set is determined by spacing

CNU Roller structure of pair-roll crusher for bentonite

The utility model discloses a roller structure of a pair-roll crusher for bentonite, which comprises a roller body, a rotary shaft, end covers and a frame. The rotary shaft fixed onto the frame is fixed onto the end covers which are fixed to two ends of the cylindrical roller body respectively, an annular groove is arranged on the lateral side of the roller body,

Roll Crushers TAKRAF TAKRAF GmbH

25: 2,500 mm pitch circle roll diameter. 37: 3,700 mm roll length. Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing

Quad Roll Crushers McLanahan

It is the heaviest-duty model of Quad Roll Crusher that McLanahan makes, but it is not intended for very hard or abrasive rock. Designed for high-capacity applications, the Super Quad Roll Crusher is capable of

Roll Crushers Williams Crusher

A roll crusher is a type of crushing equipment used to reduce the size of materials. Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions. Before

Roll Crushers / Granulators Ludman Industries High

Four-high precision grinding mill Likewise, the Roll Crusher or Granulator is a common size reduction unit, which can successfully process a variety of materials. Additionally, the differential speed of smooth or corrugated

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

Roll Crusher HRC

Materials to be crushed are becoming more and difficult to process, high throughput capacities are required. High focus is now placed on energy consumption, and the use of energy-efficient roll crushers, with high throughput rates, is becoming increasingly important from an economic and ecological point of view.

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日The roller crusher is suitable for crushing brittle block materials in cement, chemical industry, electric power, mine, metallurgy, building materials, refractories, coal mines, and other industries. It has a

Gundlach Roll Crushers Brochure PDF Belt (Mechanical

Roll Crushers. Roll Crushers. The first and only roll crushers able to size coal, salts, potash, lime and industrial minerals in 3 dimensions. 3000 Series. 4000 Series. 5000 Series. Features/Advantages Now crush to precise product, size for maximum yield with single-stage, two-roll and two-stage, four-roll crusher designs available in four models.

Bentonite Fodamon Machinery

To crush bentonite ore, it must first be loaded into an industrial crusher. The ore can then be crushed using a range of crushing techniques such as jaw crusher, hammer crusher, roll crushing, and cone crushing. Once the ore has been crushed to the desired size, it can then be further processed or used in its raw form.

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日The roll crusher has specially designed toothed rollers that can tear large pieces of bentonite clay into small pieces, effectively reducing the size of bentonite. It

Four roller crusher fine crushing 4PG roll crusher China

The four-roll crusher is actually a new type of equipment that combines a pair of roller crusher (double smooth roller crusher) and a double tooth roller crusher. It can be combined with two smooth rollers or one smooth

Bentonite Processing Methods And Required Equipment

2020年7月10日Crushing: Large pieces of bentonite are crushed by the crusher to the fineness that can enter the mill. 4. Grinding: The crushed small pieces of bentonite are

Fine Crushing Plant With Roll Crushers Eastman Rock Crusher

2022年5月20日Four Roll Fine Crusher. Maximum Feeding: Less than 60mm. Production Capacity: 2-350 (T / h) Performance Features: It has the characteristics of low use and

Bentonite Ore Products ECPlaza

Four roller crusher: The four roll crusher is actually a new type of equipment that combines a pair of roller crusher (double smooth roller crusher) and a double tooth roller

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日Four Roll crushers are designed for larger feed sizes and high ratios of reduction at high capacities. The top stage of the Four Roll crusher is essentially made up of a double roll crusher, which is

2pg 1000*1000 Big Double Roller Crusher for Bentonite

Product Description. Company Info. Basic Info. Model NO. 2PG1000*1000. Inlet Size. 250×400mm. Condition. New. Warranty. 12 Months. After-sales Service. Long Life Time.

CNU Roller structure of pair-roll crusher for bentonite

The utility model discloses a roller structure of a pair-roll crusher for bentonite, which comprises a roller body, a rotary shaft, end covers and a frame. The rotary shaft fixed onto the frame is fixed onto the end covers which are fixed to two ends of the cylindrical roller body respectively, an annular groove is arranged on the lateral side of the roller body,

Quad Roll Crushers McLanahan

It is the heaviest-duty model of Quad Roll Crusher that McLanahan makes, but it is not intended for very hard or abrasive rock. Designed for high-capacity applications, the Super Quad Roll Crusher is capable of

Roll Crushers / Granulators Ludman Industries High

Four-high precision grinding mill Likewise, the Roll Crusher or Granulator is a common size reduction unit, which can successfully process a variety of materials. Additionally, the differential speed of smooth or corrugated

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

11.25 Clay Processing US EPA

Bentonite is aclay composed primarily of smectite minerals, usually montmorillonite, and is used largely in drillingmuds, in foundry sands, and in pelletizing taconite iron ores. Fuller’s earth is defined as a nonplasticclay or claylike material that typically is high in magnesia and has specialized decolorizing andpurifying properties.

Roll Crusher HRC

Materials to be crushed are becoming more and difficult to process, high throughput capacities are required. High focus is now placed on energy consumption, and the use of energy-efficient roll crushers, with high throughput rates, is becoming increasingly important from an economic and ecological point of view.

Fine Crushing Plant With Roll Crushers Eastman Rock Crusher

2022年5月20日Four Roll Fine Crusher Introduction. The four roll crusher is suitable for ultra-fine crushing of solid materials with compressive strength less than 260mpa and moisture content less than 20%, such as crushing iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, metal silicon, barite, basalt, granite, steel slag, water

Raymond® Roller Mill air-swept vertical ring-roll Schenck Process

The Raymond® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately. ½ -2in / 10-50mm, the roller mill can produce

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日The roller crusher is suitable for crushing brittle block materials in cement, chemical industry, electric power, mine, metallurgy, building materials, refractories, coal mines, and other industries. It has a

Roll Crushers Top 2022 Models 911 Metallurgist

US$ 12,000. 8″ Laboratory Roll Crusher. 10″ to 12″ Double Roll Crushers. US$ 27,000. Roll Crusher for Sale. The standard spring roll crusher have two horizontally mounted cylinders. The set is determined by spacing

CNU Roller structure of pair-roll crusher for bentonite

The utility model discloses a roller structure of a pair-roll crusher for bentonite, which comprises a roller body, a rotary shaft, end covers and a frame. The rotary shaft fixed onto the frame is fixed onto the end covers which are fixed to two ends of the cylindrical roller body respectively, an annular groove is arranged on the lateral side of the roller body,

Roll Crushers TAKRAF TAKRAF GmbH

25: 2,500 mm pitch circle roll diameter. 37: 3,700 mm roll length. Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing

Quad Roll Crushers McLanahan

It is the heaviest-duty model of Quad Roll Crusher that McLanahan makes, but it is not intended for very hard or abrasive rock. Designed for high-capacity applications, the Super Quad Roll Crusher is capable of

Roll Crushers Williams Crusher

A roll crusher is a type of crushing equipment used to reduce the size of materials. Size reduction is accomplished by compressing feed material between two cylindrical rollers that rotate in opposite directions. Before

Roll Crushers / Granulators Ludman Industries High

Four-high precision grinding mill Likewise, the Roll Crusher or Granulator is a common size reduction unit, which can successfully process a variety of materials. Additionally, the differential speed of smooth or corrugated

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年5月27日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

Roll Crusher HRC

Materials to be crushed are becoming more and difficult to process, high throughput capacities are required. High focus is now placed on energy consumption, and the use of energy-efficient roll crushers, with high throughput rates, is becoming increasingly important from an economic and ecological point of view.

HOW FOUR ROLL CRUSHERS WORK Gongyi Forui

2021年9月23日The roller crusher is suitable for crushing brittle block materials in cement, chemical industry, electric power, mine, metallurgy, building materials, refractories, coal mines, and other industries. It has a

Gundlach Roll Crushers Brochure PDF Belt (Mechanical

Roll Crushers. Roll Crushers. The first and only roll crushers able to size coal, salts, potash, lime and industrial minerals in 3 dimensions. 3000 Series. 4000 Series. 5000 Series. Features/Advantages Now crush to precise product, size for maximum yield with single-stage, two-roll and two-stage, four-roll crusher designs available in four models.

Bentonite Fodamon Machinery

To crush bentonite ore, it must first be loaded into an industrial crusher. The ore can then be crushed using a range of crushing techniques such as jaw crusher, hammer crusher, roll crushing, and cone crushing. Once the ore has been crushed to the desired size, it can then be further processed or used in its raw form.